Maybe? There are many different factors to be consider before filling.

All dive cylinders in New Zealand must be in ‘test’ before they can be filled.

Cylinders are tested every 12 months from their date of manufacture. Tanks are then stamped or tagged with their last test date so Air Fillers can determine if they can be filled.

There are two different tests – the Hydrostatic Test and the Visual Test.

Hydrostatic Tests are designed to test the integrity of the metal by filling the cylinder with water and pressurizing it to test for strength and leaks. A visual test is conducted before and after the hydrostatic test.

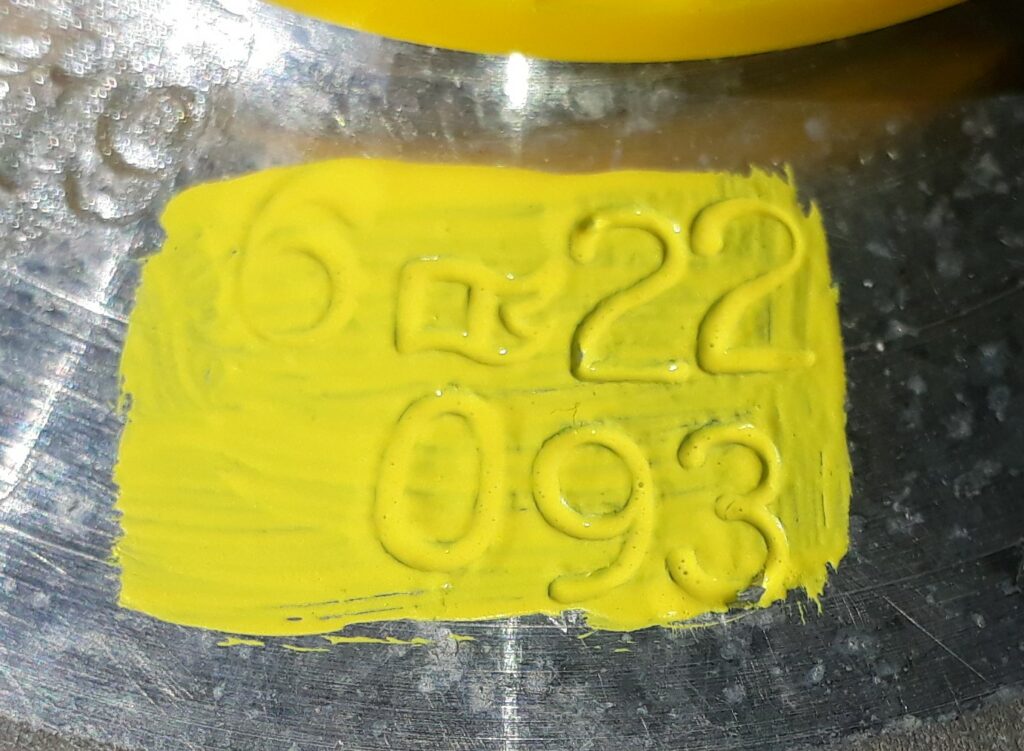

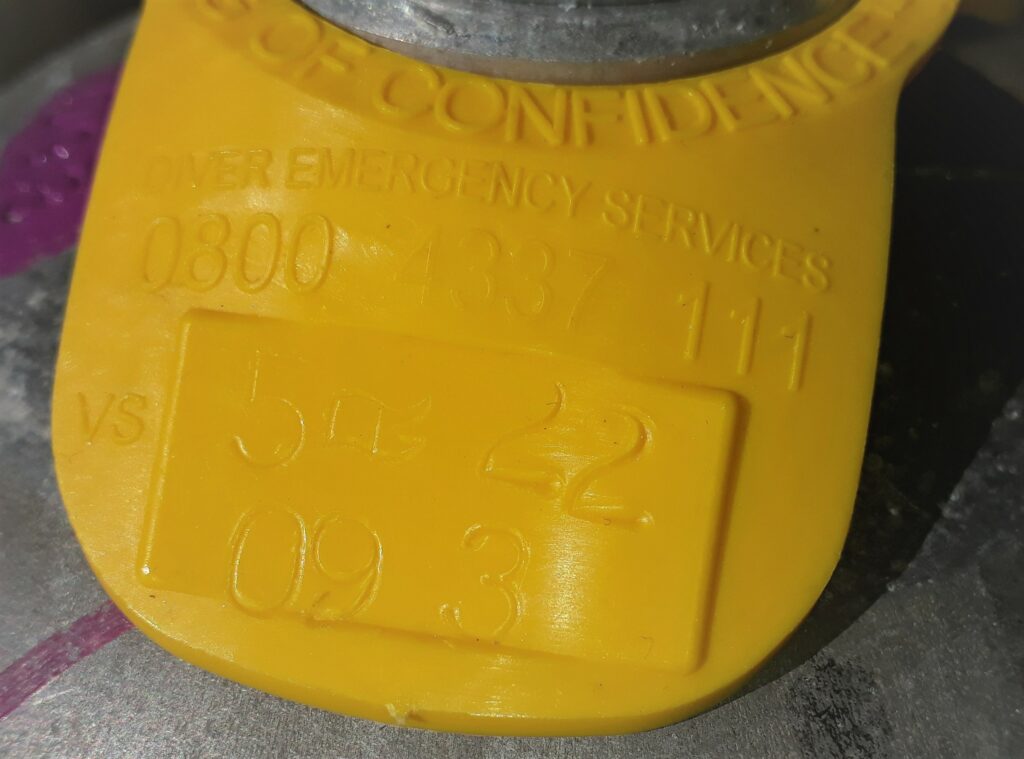

This test date, MM YY, is stamped onto your tank’s shoulder with the tester’s symbol (ours is a flag) in between and the Test Station’s number – in our case – 093, below. We also add a neck tag for easy recognition with H and the month stamped on it.

The Visual Test does exactly as it names suggests – and gives your tank a once over inside and out. Externally the tank is checked for signs of corrosion and evidence of damage such as scratches or dents. The valve is then removed so we can inspect for internal corrosion and check the threads for damage or cracks. A tank is more likely to fail at this point due to the interaction between the brass valve and the steel /aluminum tank. This test date is stamped onto a tag (or a cable tie around the neck).

Fillers may refuse to fill a cylinder that is in test due to external damage to the tank, inability to read the markings on the tank or a faulty valve.

Some cylinders cannot be tested as they have incomplete or illegible markings or have been condemned by Worksafe. If you are unsure of the status of your tank bring it in for some advice, all our staff are certified air fillers and Claire is a Periodic Tester and can test your tanks on site.

Anyone filling dive cylinders in New Zealand is required by law to hold an Air Fillers Certification. With a NZU Certified Instructor onsite we can arrange a suitable course for you.